Nextion Editor Overview

Nextion Editor Overview

Nextion Editor is a free human-machine interface (HMI) GUI development software for Nextion Basic Series, Discovery Series, Enhanced Series, and Intelligent Series. The software offers an easy way to create an intuitive and superb touch user interface even for beginners. Add a static picture as a background, define functions by components, you can make a simple GUI in minutes. The easy Drag-and-Drop components and simple ASCll text-based instructions will dramatically reduce your HMI project development workloads and develop projects rapidly in a cost-effective way. The Nextion product is the best balance HMI solution between cost and benefit with a low and decreased learning curve.

Nextion Editor Features

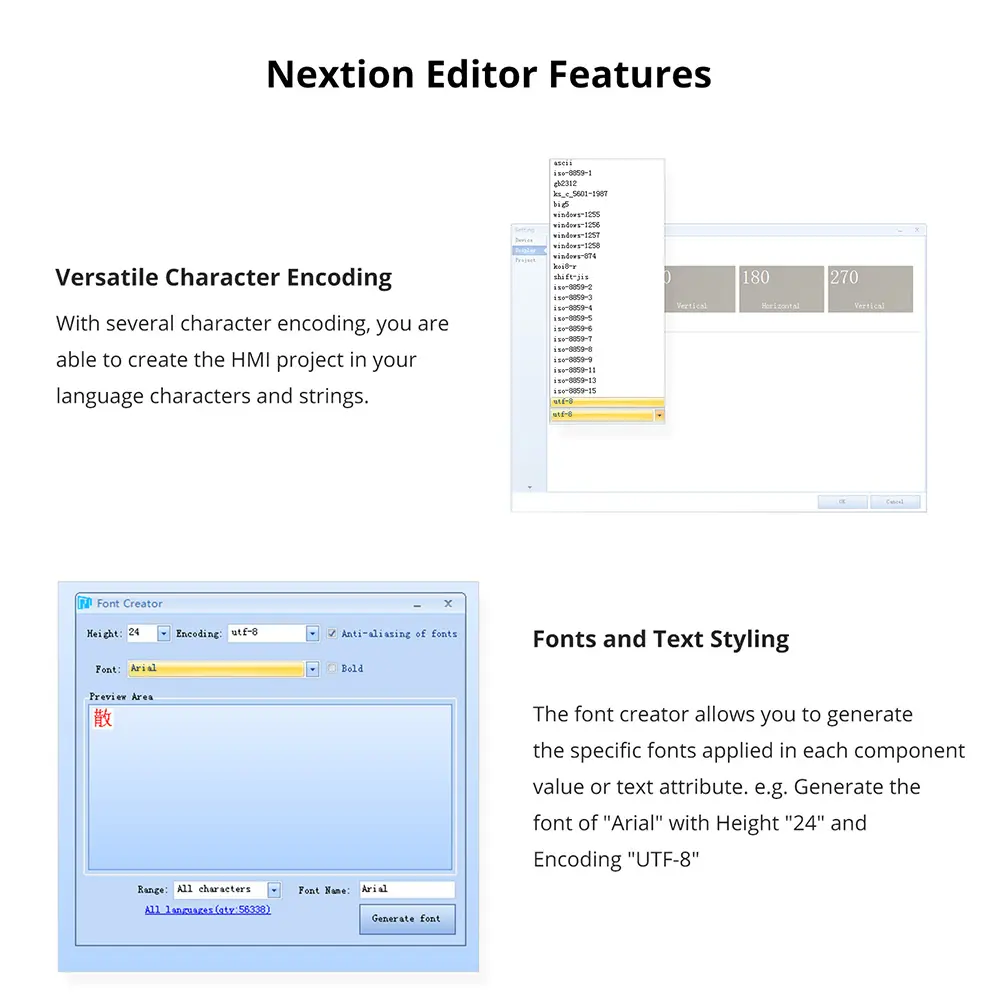

Versatile Character Encoding

Nextion Editor Features

Versatile Character Encoding

With several character encoding, you are able to create the HMI project in your language characters and strings.

Fonts and Text Styling

The font creator allows you to generate the specific fonts applied in each component value or text attribute. e.g.Generate the font of “Arial” with Height “24” and Encoding “UTF-8”

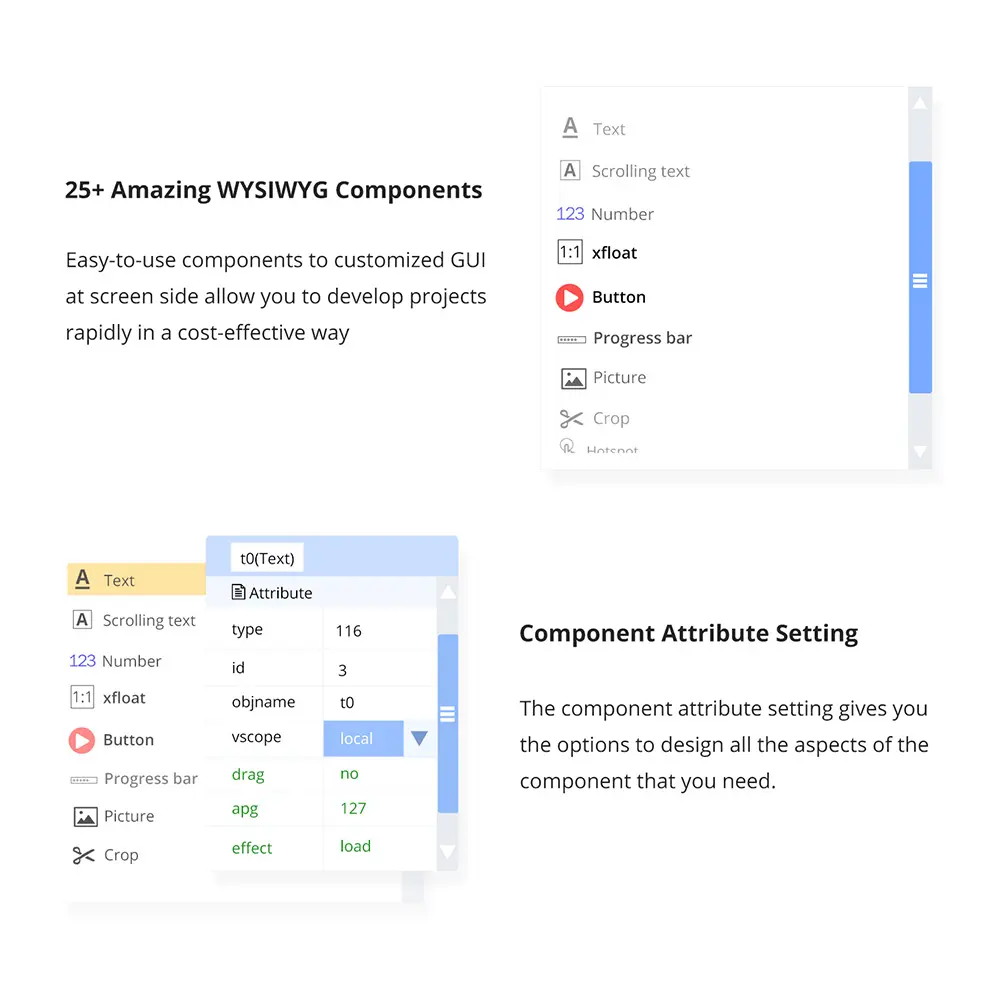

25+Amazing WYSIWYG Components

25+Amazing WYSIWYG Components

Easy-to-use components to customized GUI at screen side allow you to develop projects rapidly in a cost-effective way

Component Attribute Setting

The component attribute setting gives you the options to design all the aspects of the component that you need.

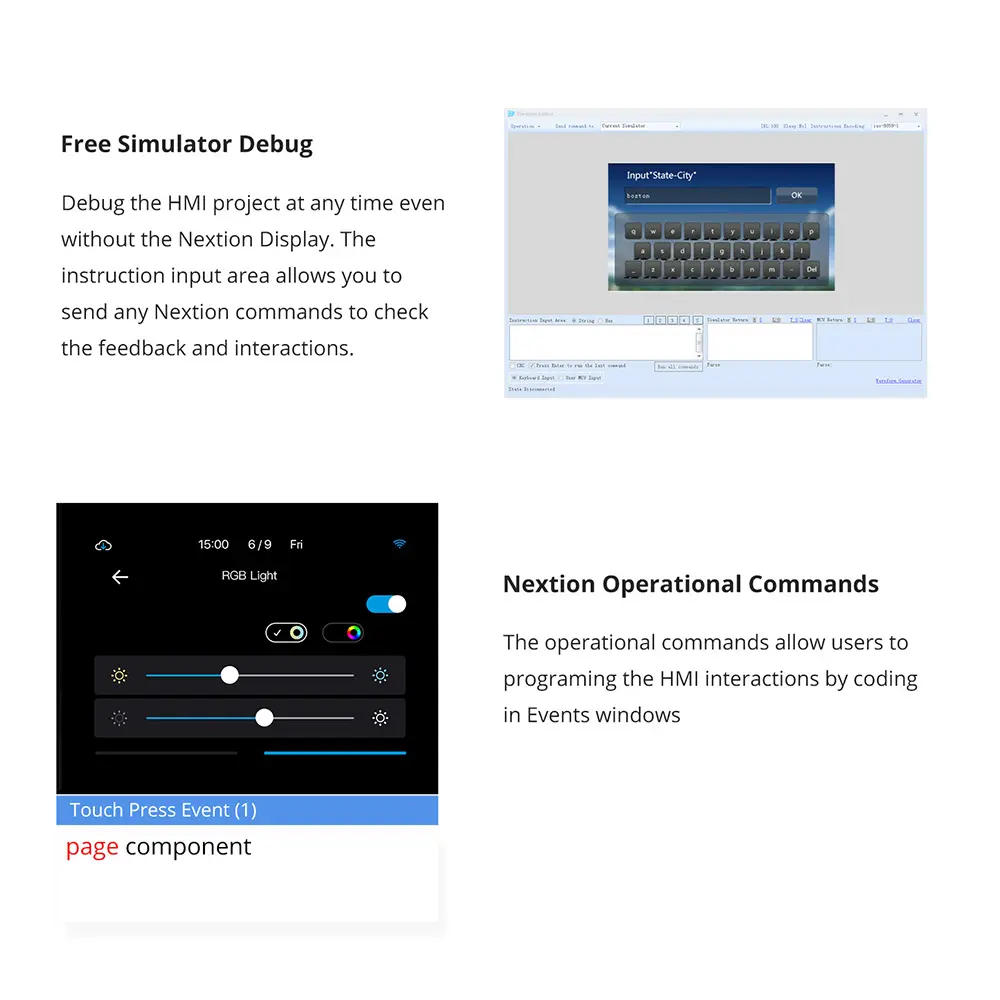

Free Simulator Debug

Free Simulator Debug

Debug the HMI project at any time even without the Nextion Display.The instruction input area allows you to send any Nextion commands to check the feedback and interactions.

Nextion Operational Commands

The operational commands allow users to program the HMI interactions by coding in Events windows

Text-based Instruction Set

Text-based Instruction Set

Simple ASCll text based instructions will dramatically reduce your HMI project development workloads

Support Simple Assignment Operators

To handle the calculation and assignment for the text and Numeric data, the simple assignment operators help.

Documents

Please visit our

wiki page for more information about this product. Any suggestions for improvement, such as correcting errors, adding more demo codes or tutorials, will be highly appreciated.

Data Sheet

Nextion Editor Overview

Nextion Editor is a free human-machine interface (HMI) GUI development software for Nextion Basic Series, Discovery Series, Enhanced Series, and Intelligent Series. The software offers an easy way to create an intuitive and superb touch user interface even for beginners. Add a static picture as a background, define functions by components, you can make a simple GUI in minutes. The easy Drag-and-Drop components and simple ASCll text-based instructions will dramatically reduce your HMI project development workloads and develop projects rapidly in a cost-effective way. The Nextion product is the best balance HMI solution between cost and benefit with a low and decreased learning curve.

Nextion Editor Overview

Nextion Editor is a free human-machine interface (HMI) GUI development software for Nextion Basic Series, Discovery Series, Enhanced Series, and Intelligent Series. The software offers an easy way to create an intuitive and superb touch user interface even for beginners. Add a static picture as a background, define functions by components, you can make a simple GUI in minutes. The easy Drag-and-Drop components and simple ASCll text-based instructions will dramatically reduce your HMI project development workloads and develop projects rapidly in a cost-effective way. The Nextion product is the best balance HMI solution between cost and benefit with a low and decreased learning curve. Nextion Editor Features

Versatile Character Encoding

With several character encoding, you are able to create the HMI project in your language characters and strings.

Fonts and Text Styling

The font creator allows you to generate the specific fonts applied in each component value or text attribute. e.g.Generate the font of “Arial” with Height “24” and Encoding “UTF-8”

Nextion Editor Features

Versatile Character Encoding

With several character encoding, you are able to create the HMI project in your language characters and strings.

Fonts and Text Styling

The font creator allows you to generate the specific fonts applied in each component value or text attribute. e.g.Generate the font of “Arial” with Height “24” and Encoding “UTF-8”

25+Amazing WYSIWYG Components

Easy-to-use components to customized GUI at screen side allow you to develop projects rapidly in a cost-effective way

Component Attribute Setting

The component attribute setting gives you the options to design all the aspects of the component that you need.

25+Amazing WYSIWYG Components

Easy-to-use components to customized GUI at screen side allow you to develop projects rapidly in a cost-effective way

Component Attribute Setting

The component attribute setting gives you the options to design all the aspects of the component that you need.

Free Simulator Debug

Debug the HMI project at any time even without the Nextion Display.The instruction input area allows you to send any Nextion commands to check the feedback and interactions.

Nextion Operational Commands

The operational commands allow users to program the HMI interactions by coding in Events windows

Free Simulator Debug

Debug the HMI project at any time even without the Nextion Display.The instruction input area allows you to send any Nextion commands to check the feedback and interactions.

Nextion Operational Commands

The operational commands allow users to program the HMI interactions by coding in Events windows

Text-based Instruction Set

Simple ASCll text based instructions will dramatically reduce your HMI project development workloads

Support Simple Assignment Operators

To handle the calculation and assignment for the text and Numeric data, the simple assignment operators help.

Text-based Instruction Set

Simple ASCll text based instructions will dramatically reduce your HMI project development workloads

Support Simple Assignment Operators

To handle the calculation and assignment for the text and Numeric data, the simple assignment operators help.